CHICAGO — The restaurant industry needs 500,000 more workers by the end of the year to ease a chronic undersupply of labor, National Restaurant Association CEO Michelle Korsmo said during the keynote event at the NRA Show on Sunday. In other words, the market has about two job openings for every worker looking for a job, Korsmo said.

This employment gap has given workers more bargaining power, driving up labor costs and making it harder for restaurants to stay fully staffed and open for their full hours. For many restaurants, back-of-house robotics and smart kitchen equipment are key to meeting diner expectations despite low staffing levels. Such technological adoption could become so prevalent, Korsmo said, that it will reshape the industry by 2030.

“[In 2030] facilities will be smaller, with more automated kitchens, and different from the typical layout. Tech costs will be a standard line item in everyone's P&L, and the average number of employees will decline,” Korsmo predicted.

The NRA Show featured a wide variety of technology providers that are pushing the industry toward that future — saving a few minutes here, a whole job role there. The tech on display ranged from robotic arms capable of running a fry station to a safety software system that can detect contaminants on an employee’s hands. Restaurant Dive interviewed representatives of several companies about their innovative products, what differentiates them from competitors, their price points, and their labor saving potential.

Robotic fry stations

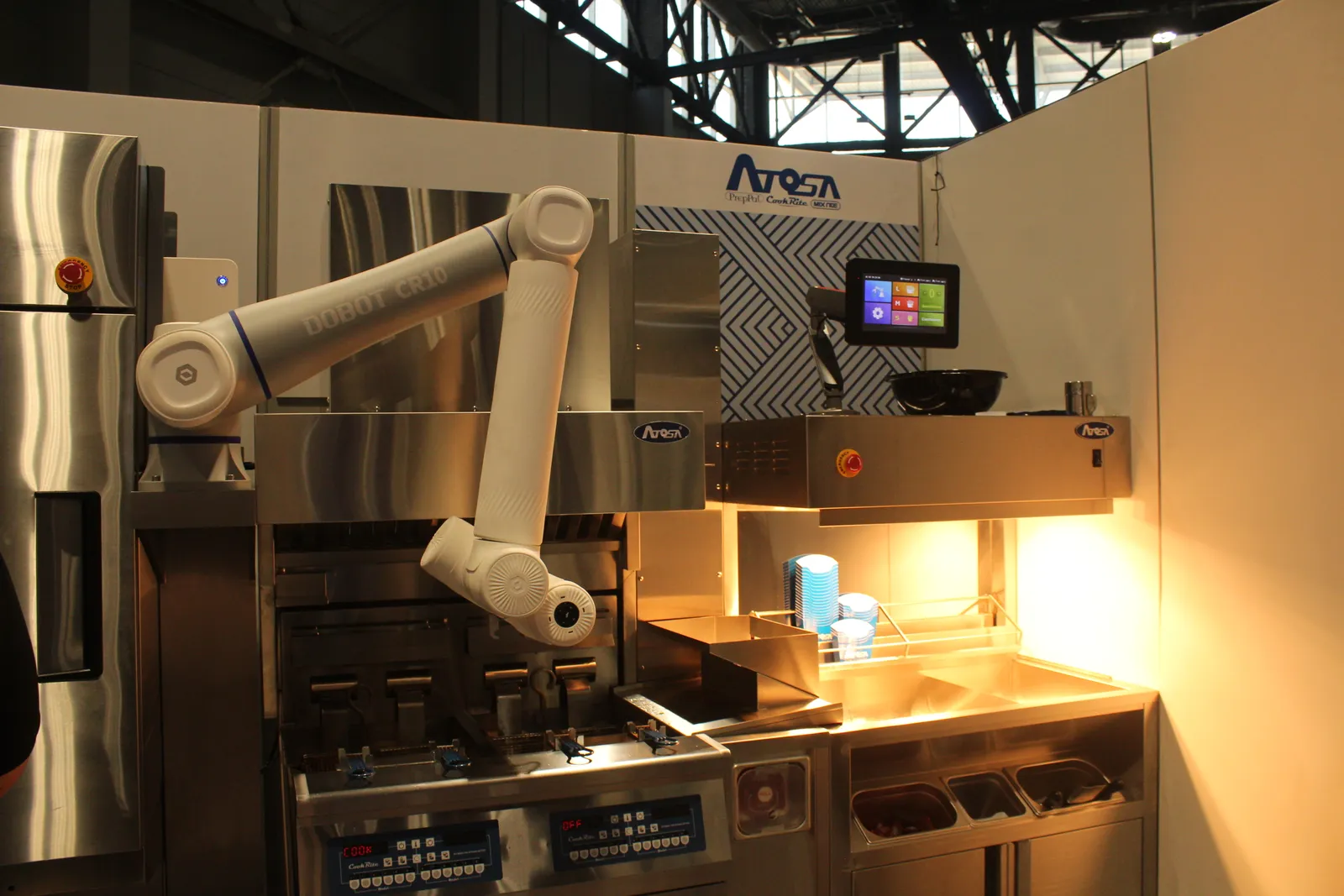

Allen Ogle stood directly in the path of the robotic fryer arm, his back to the fry baskets. The machine, carrying a basket of fries fresh out of the fryer, shifted along its predetermined track. The arm struck Ogle, but it was only the softest of touches. Ogle, a technical support specialist at Atosa Catering Equipment, grinned. Maury Rams, Atosa’s vice president of international sales, explained the robot arm — called Intelligent French Fry Robotic Solution — is covered in a conductive rubber that detects when an object is in its path.

The arm stops within two centimeters of touching something, so it shouldn’t injure or knock over a worker, Ogle said. When the arm, moving at a low speed, hit Ogle, it stopped immediately. This is one of the features designed to make Atosa’s french fry robot more attractive to operators. The automatic stop feature means the arm is safe for workers to move around, eliminating the need for large safety glass cases like those found around some competing robot arms.

Free of a safety case, the arm is nimble and takes up a smaller portion of valuable kitchen space. The frying arm can also use a ventless hood or fit under most standard vent hoods, Ogle said, so it lowers the cost of renovation and installation.

Atosa is still working on automating the salting portion of the station, though Ogle said that would be ready by the end of the year. With the salt station automated, Ogle estimated the equipment could take the place of one worker at the fryer and a second at the salt and packaging station.

Cost: The station, once complete, will cost between $80,000 and $90,000, according to Ogle, and will be capable of frying 30 pounds of fries in 20 minutes, Rams said.

Smart combi ovens

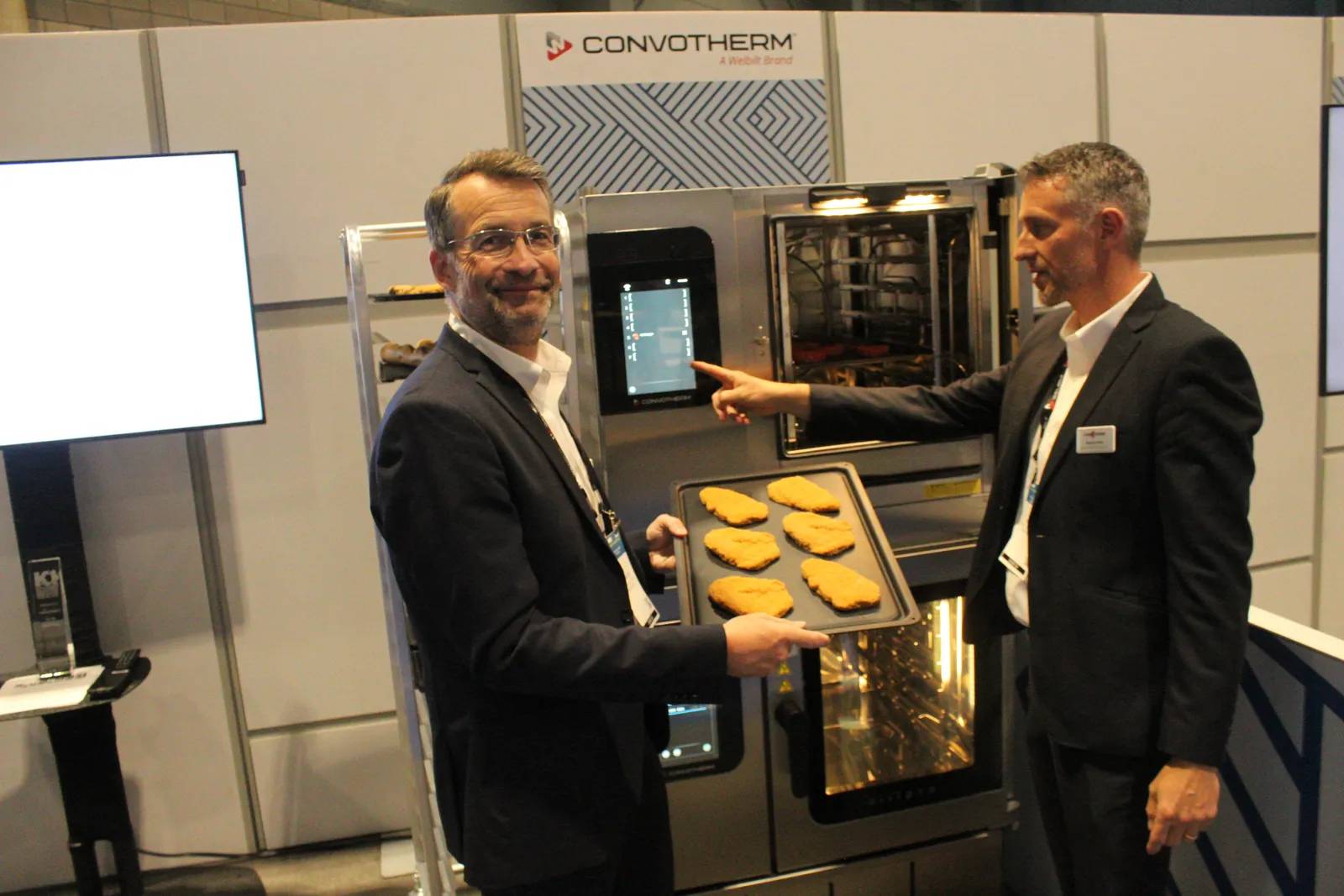

Convotherm’s oven knows what you put into it, said Arndt Manter, a product manager for the German company. Manter and his colleague Hannes Wild loaded the oven with trays covered in simulated hamburgers and schnitzel.

The oven uses a camera to identify what product, and what amount, is being put into it, meaning it can estimate how long and how hot it will have to run to cook the product. It warns employees when they’ve loaded it with too much product for its preset temperatures. When Wild loaded the schnitzel, the oven flashed an alarm on its display, warning that freshness cannot be assured if production moves too quickly.

The Convotherm oven uses artificial intelligence developed by PreciTaste and a camera, height sensors, and heating and cooling systems to cook anything from steamed broccoli to steak, Manter said.

“It understands what kind of food item you put in and on which [oven] level you put it in. And then it acts and goes into the cookbook and pulls out the right profile,” Manter said. “By closing the door it starts the cooking.” Users can upload item profiles to the cookbook, and once those are in, the machine can cook according to the recipe without humans needing to adjust the temperature or timing at all, Wild said.

The system is in use already at the European supermarket chain REWE, where Manter said it saves the store bakers about an hour out of every eight-hour shift, and has the added benefit of enabling REWE to run its ovens even when a trained baker is not available. These features have enabled REWE to improve the freshness of its baked goods and increase sales of baked items by at least 25%, according to Manter.

Cost: The Convotherm smart oven is new to the North American market, so the company has not yet determined the pricing for American buyers.

Hygiene scanning and safety software

PathSpot has developed an optical scanner that can detect the host material for E-Coli, listeria, norovirus and salmonella, all of which are generally transmitted through feces. The scanner, deployed next to a handwashing station, can see how effectively an employee has washed their hands, said Dutch Waanders, co-founder and chief technology officer of PathSpot said.

“Visible light fluorescence spectroscopy is the technical term, but essentially the way that light reflects off the contaminants is unique,” Waanders said “We can use a system of unique LEDs and cameras and filters and a machine learning algorithm to determine if that contamination is present.”

The system codes employee results by color. Green means a contaminant was not detected, yellow means a contaminant was present but the employee washed their hands again and passed a second scan, and red indicates a failure without corrective action. But PathSpot’s tech goes beyond handwashing, with the scanner serving as the hub for an integrated safety software system.

“That incorporates temperature monitoring, line checks, opening closing checklists, label printing, task management, audit notes, all of the above,” Waanders said. The company has worked with a variety of hardware partners to integrate existing sensors into its system through the internet of things.

“We want to make sure all of the devices that we have within the facility are all syncing with each other, and syncing back to our cloud. So the data is all accessible in the same places,” Waanders said. KB Bateman, who does communications for the company, estimated it could save a restaurant about 20 minutes a day by aggregating all the safety check information. While the labor savings are minimal, the savings from preventing foodborne illness and associated brand damage are intangible, Bateman said.

Cost: Bateman said the company’s pricing is low, as Pathspot is aware of the thin margins at most restaurants, but declined to share specific numbers.

Robotic burger stations

Luis Astacio, a marketing representative for Aniai, a South Korean firm that manufactures a robotic grill, said his company’s robotic grill can cook eight patties, each ranging between four and six ounces, in about 90 seconds.

To achieve those cook times, a worker places the patties on the cooking surface, which the machine then raises to a second heating element, which cooks the top of the burger simultaneously, similar to a clamshell grill. But this grill uses cameras to monitor the color and temperature of the patties, meaning the machine knows when burgers are done cooking, Astacio said.

It’s self-cleaning too, with a scraper that removes grease and residue between cooking sessions. Astacio said the proprietary AI can use the cameras on the machine to detect some contaminants in protein, meaning it can also improve food safety.

These features, Astacio estimated, save labor roughly equivalent to one employee.

“In terms of dollars and cents when you're thinking long term in terms of our [labor] crisis, currently, it makes sense to go with automation,” Astacio said.

Cost: The price is about $130,000 for one unit, but the company also offers a subscription service for $3,500 monthly.